Easily track stock levels and inventory status to reorder on time and maintain the right balance.

AgES brings over 15 years of ERP and enterprise application expertise, delivering a proven solution for end-to-end material and inventory control. Our software is built to address real challenges—manual processes, stock inaccuracies and compliance risks—by providing a simple, scalable and reliable platform.

Accessible anywhere, anytime, without user-based licensing costs.

Automates approvals, planning and material flow with complete visibility.

Eliminates non-moving and dead stock across plants.

Ensures accuracy and traceability across every stage.

Single-click access to critical data, KPIs and compliance insights.

Keeps teams proactive and reduces idle time.

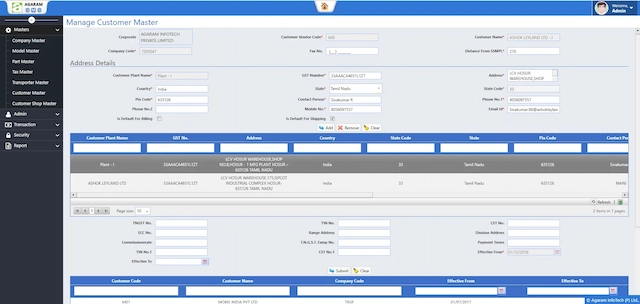

AgES Inventory is designed to make GST compliance simple, accurate and fully audit-ready. Every transaction in the system is linked with the correct tax information to ensure seamless compliance.

AgES Invoice Management System is designed to simplify your entire sales and billing cycle.

Generate accurate reports anytime.

Minimize manual work and human error.

Manage stock seamlessly across warehouses, plants and sites.

Ensure timely replenishment and avoid stock-outs.

Optimize picking, storage and dispatch.

Achieve full traceability for materials and finished goods.

Stay informed about expiries, shortages, or pending approvals.

Insights for better planning and cost control.

Replace spreadsheets and paperwork with a centralized digital system.

Optimize stock levels with demand-based planning.

Automated processes free up staff time for higher-value tasks.

Barcode/RFID ensures accuracy in receipts and issues.

GST-ready and FIFO-based records simplify inspections.

Integrated platform supports scale-up without disruption.

AgES Inventory is designed to adapt to diverse sectors and operational needs:

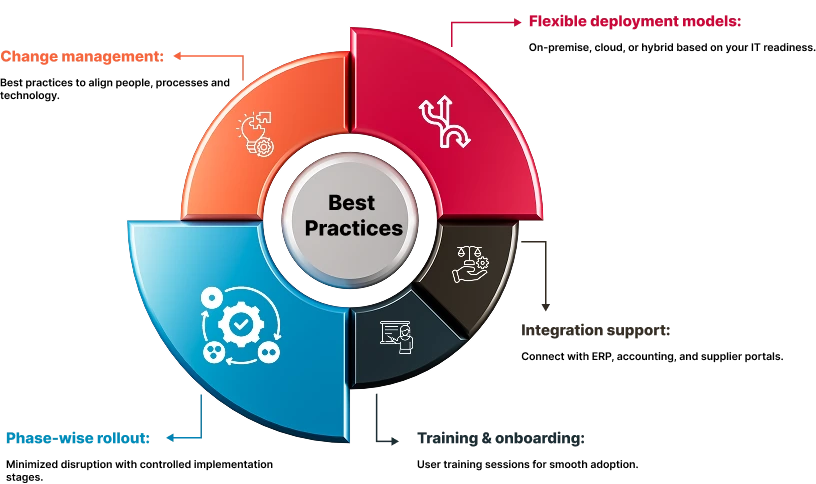

AgES is more than software—it’s a complete implementation approach ensuring success: