Core Modules for Asset Tracking ERP Software

Asset Management

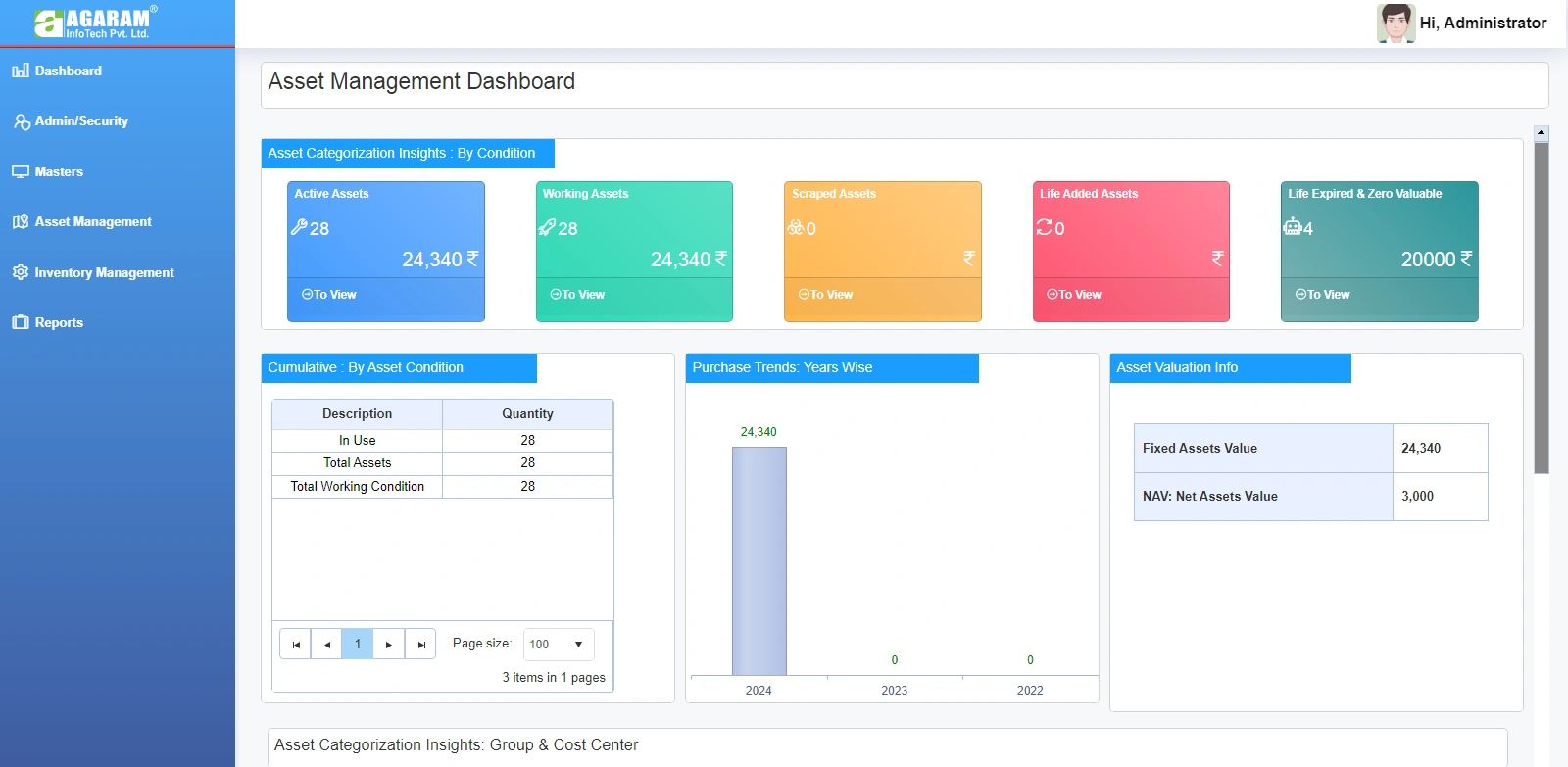

Asset Dashboard

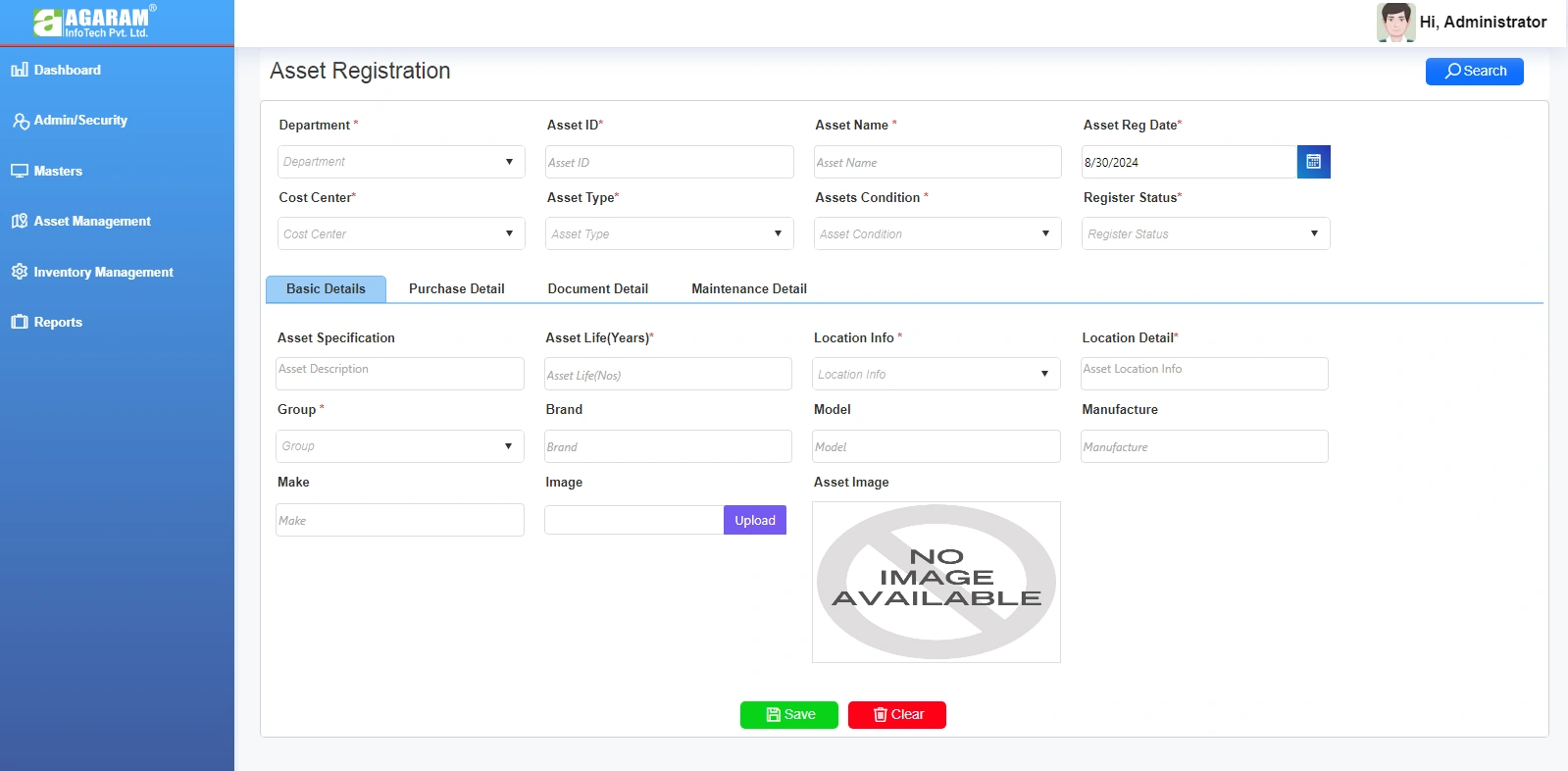

Asset Registration

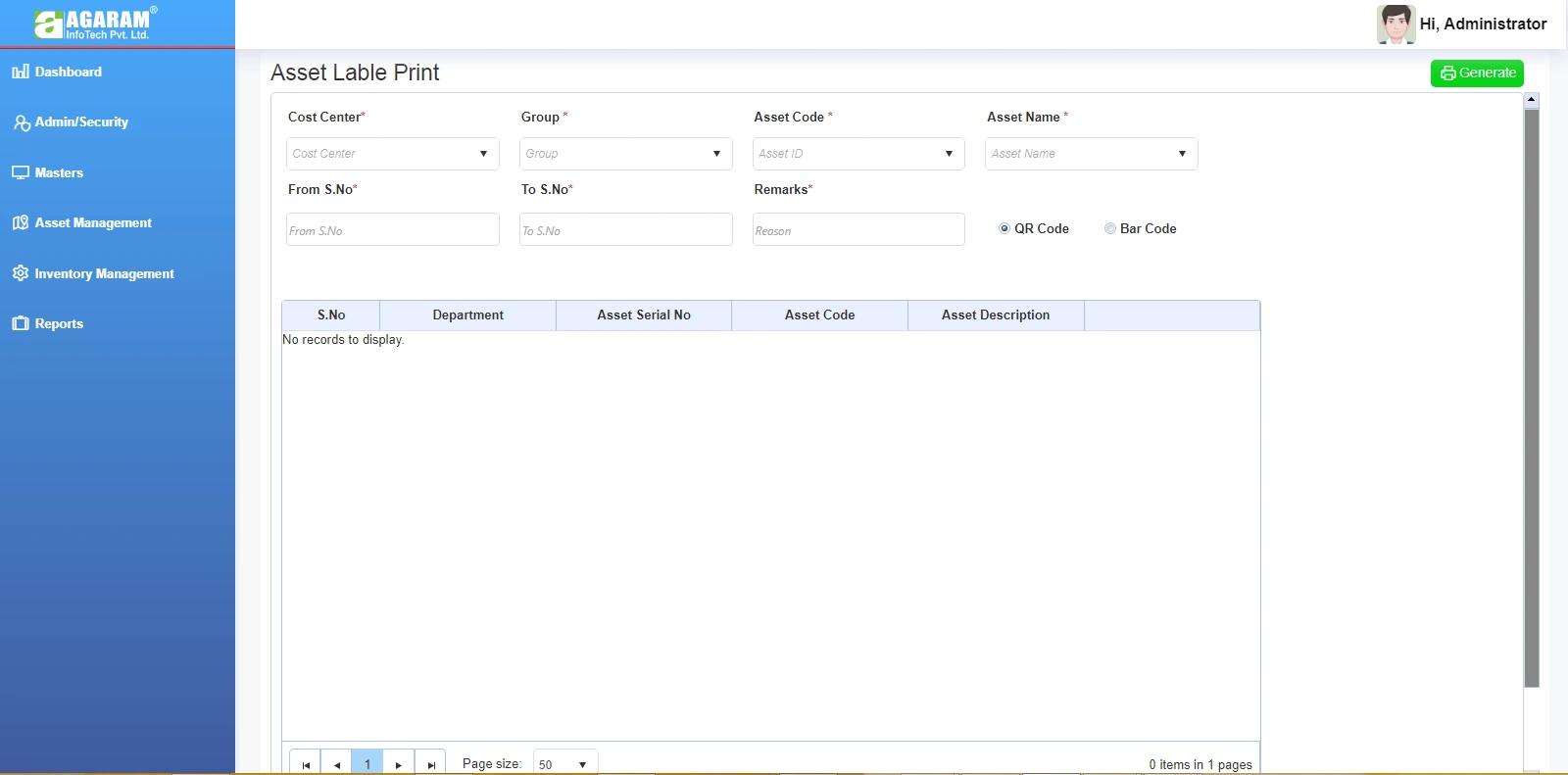

Asset Label Print

Asset RFID Mapping

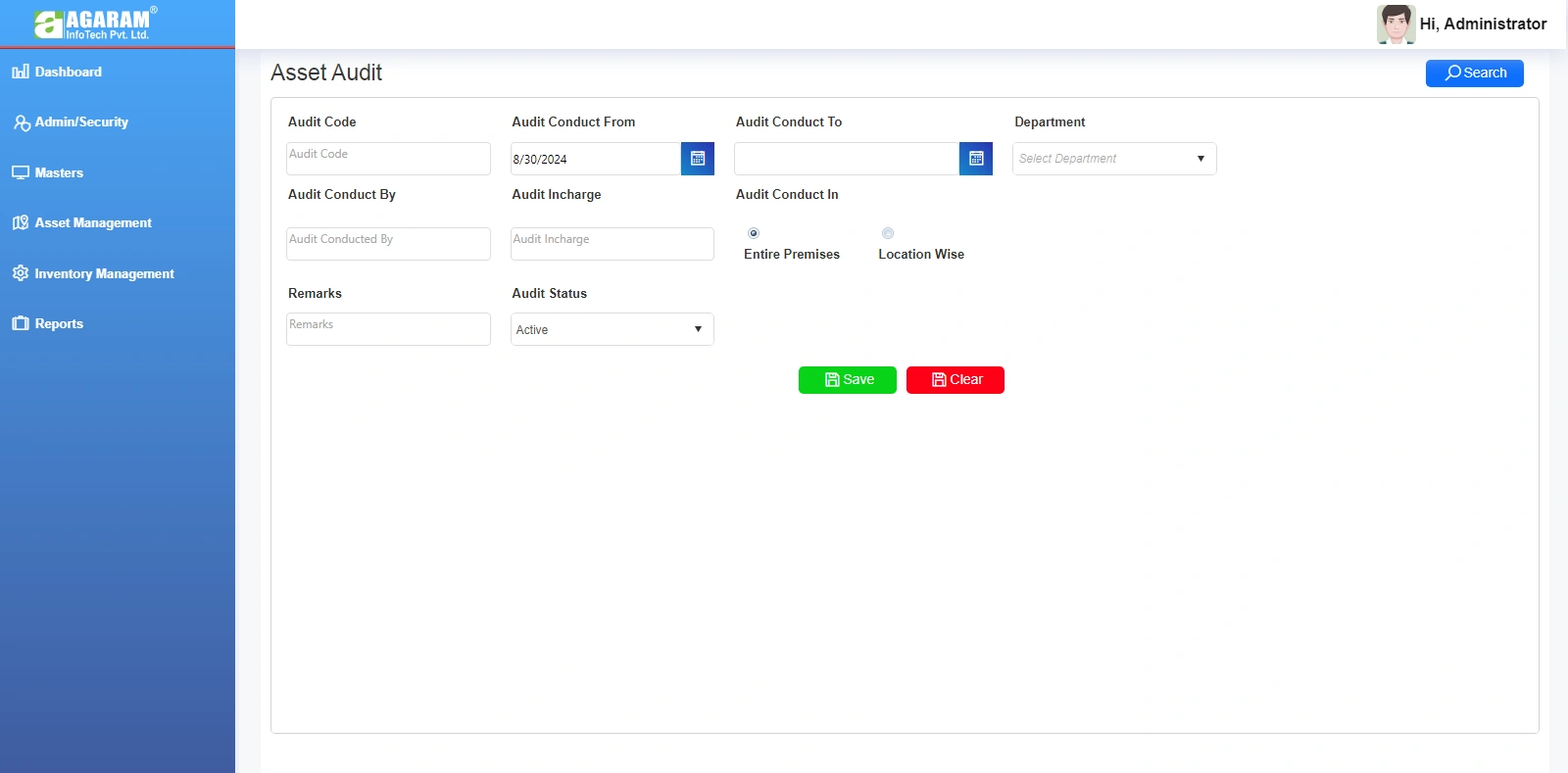

Asset Audit

Asset Audit Verification

The primary objective of this project is to develop a sophisticated web-based application utilizing RFID, QR-Code, or Barcode solutions for effective Asset Management. This system aims to streamline asset tracking and management processes, thereby reducing manual workload and fostering an integrated environment for organizational efficiency. The ultimate goal is to revolutionize asset management practices, enhancing operational efficiency and elevating customer engagement at Client Place.

Highlights

- Implement a solution to simplify and automate asset tracking processes.

- Minimize manual efforts and errors by automating asset management tasks.

- Create an integrated environment for seamless operations across different departments.

- Improve overall organizational efficiency through better asset management practices.

- Enhance interactions with clients by providing a more responsive and efficient asset management system.

Trusted By

Frequently Asked Questions

Every time the selection of vendor for Raw materials is a time & resource consuming activity? How can you optimize it?The application compares rates and suggests the best 3 suppliers for each raw material based on the quotes received from various suppliers. It also offers the feature to block suppliers based on their service quality.

We manually make the brewing plan, which is not efficient. Does your software offer any solution to this?

The application makes the most optimum brewing plan based on the sales forecast and the stock available in the inventory. This plan can be updated by the user on a daily basis, based on the customer requirement. The system also generates the material requirement plan based on the projected production.

Managing the quality of output is a very crucial activity in breweries. Does the application handle this aspect of our business?

Strict quality control measures are imposed at every stage by the application. The Raw materials are subject to incoming inspection and only the approved ones are entered in to the system. After every stage of brewing the output of the process is subject to quality testing and only on confirmation of the quality it moves to the next process in pipeline.

We manually maintain the material consumption for different processes & maintenance activities. How will you enhance this?

Application captures the real time consumption of materials like water, Carbon-di-oxide, energy, etc., for different processes. It provides equipment wise and process wise material consumption details. It also offers you maintenance history and service cost details for any selected period / machine.

We make indent entries manually, it becomes difficult to track indent status. What help does your s/w offer?

The system seamlessly captures every detail of the indent. Offers feature to track the status of the indent, you can easily find if it is completed, partially completed, expired or has to be revalidated. Alerts are issued ahead of the revalidation date for the expired ones.

Complaint Management System

Complaint Management System