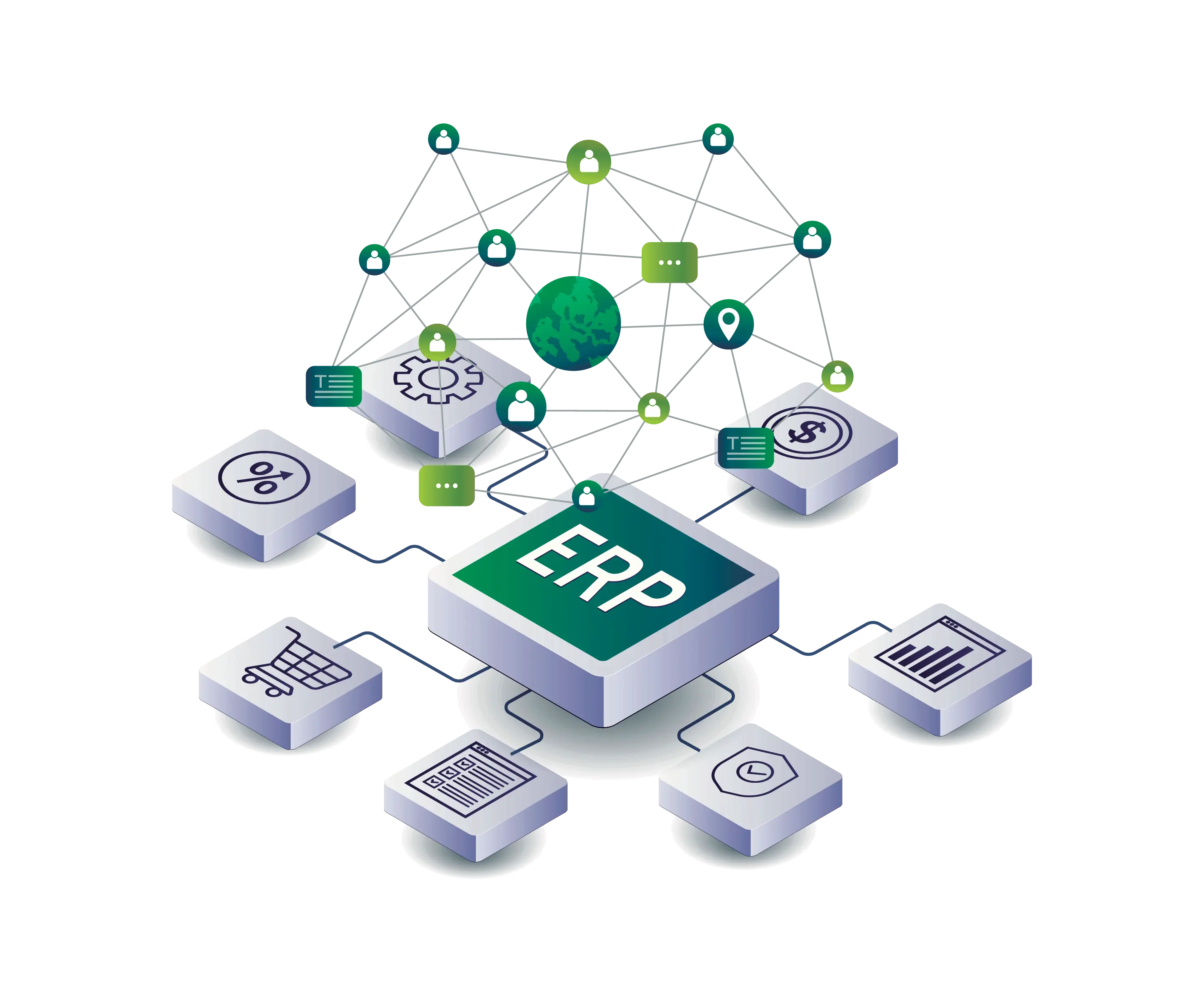

A complete web-based ERP solution designed to simplify, integrate and optimize your manufacturing processes—from procurement to production, quality control, Sales and Distribution.

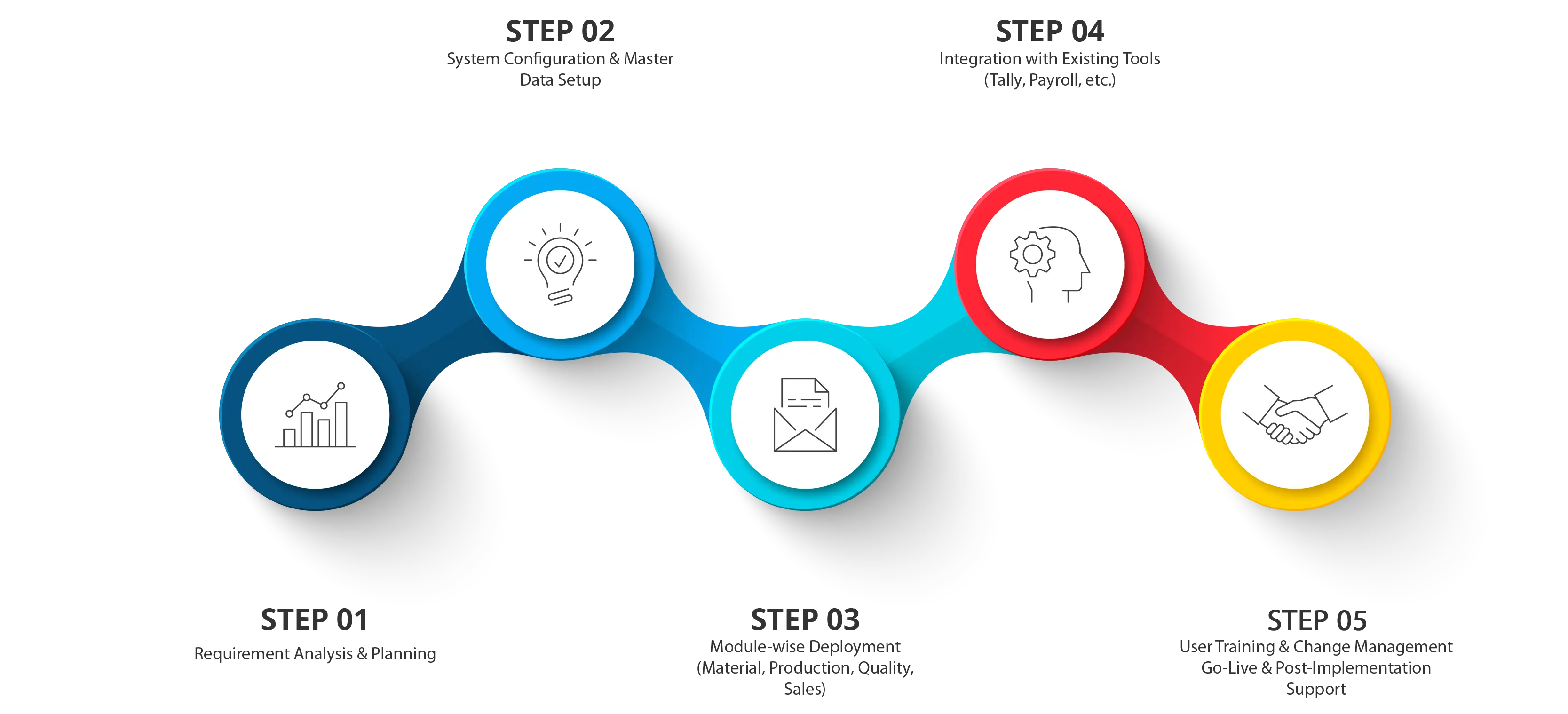

Managing manufacturing operations manually or through disconnected systems often leads to inefficiencies, delays and costly errors. Our AgES ERP bridges this gap by providing a fully integrated, user-friendly and scalable platform that empowers manufacturers to:

Procurement, Production and Sales by connecting all workflows in one system.

Reduce Manual Work and Scattered records with a single, well-structured platform.

Automate Approvals, Alerts and reports to save time and keep processes on track.

Improve Planning and stock visibility with accurate, up-to-date inventory data.

Increase efficiency and productivity while supporting faster business decisions.

Our Manufacturing ERP comes with powerful modules to cover every stage of your business:

Automates purchase requests, approvals, GRN, stock updates and issue slips.

Route sheets, job cards, batch tracking, BOM backlash and daily/monthly planning.

Incoming, inline and final inspections with rejection/rework tracking.

Manage proforma invoices, sales orders, dispatches and customer returns.

Integrated employee records, approvals and payroll processing.

Instant MIS, drill-down analytics, corporate calendar and automated alerts.